2019-05-11 17:11:55

2019-05-11 17:11:55Developed countries control high-end markets

With the rapid development of global economy and information technology, countries have entered the technical and popularization stages of industrial automation, office automation, family modernization, agricultural modernization and military equipment modernization. As an important basic component of these technologies and systems, the demand of permanent magnet motors is increasing, the market space is expanding year by year, and the development momentum is good.

With the continuous development of the global permanent magnet motor industry, Japan, Germany, the United States, the United Kingdom, Switzerland, Sweden and other well-known brand companies rely on their decades of production experience and key technology of permanent magnet motor, and control most of the high-end, precision, new permanent magnet motor technology and products.

For example, Japan has done a lot of research and development work in the fields of high efficiency, silence and high performance of permanent magnet motor for industrial servo, so it has great advantages in technology. The micro-motor equipment produced by Japan has high control accuracy, low power consumption, long life and low cost, small size and other competitive advantages, and it is also at the forefront of the world in technology. Most of the world's high-end permanent magnet motor market.

At present, the main manufacturers of permanent magnet motors in Japan are Japan Electric Co., Ltd., Japan Asmo Co., Ltd., Japan Electric Co., Ltd., and Japan Marlboro to Motor Co., Ltd.

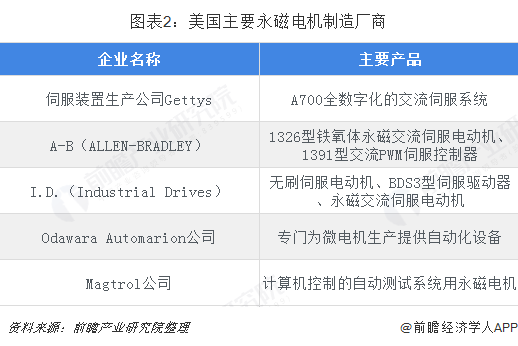

The motor development in the United States is later than that in Japan. In the United States, the design of induction motor and the development of its control strategy are relatively mature, so the drive motor of electric vehicle is mainly based on induction motor. However, the research on permanent magnet synchronous motor has also been carried out in the United States, and the progress is rapid. For example, the permanent magnet synchronous motor developed by SatCon Company uses stator double winding technology, which not only enlarges the speed range of the motor, but also effectively utilizes the voltage of the inverter. The winding current is low and the motor efficiency is high. At present, Gettys, A-B, I.D, Odawara Automarion and Magtrol are the main manufacturers of permanent magnet motors in the United States.

However, the development of permanent magnet motor industry in the United States mainly focuses on military micro-motors. The research and product level of military micro-motors in the United States is in the leading position in the world. The majority of all kinds of micro-motors used in military equipment and electronic devices in western countries are supplied by several major manufacturers in the United States. The US military standards for micro-motors have become international standards.

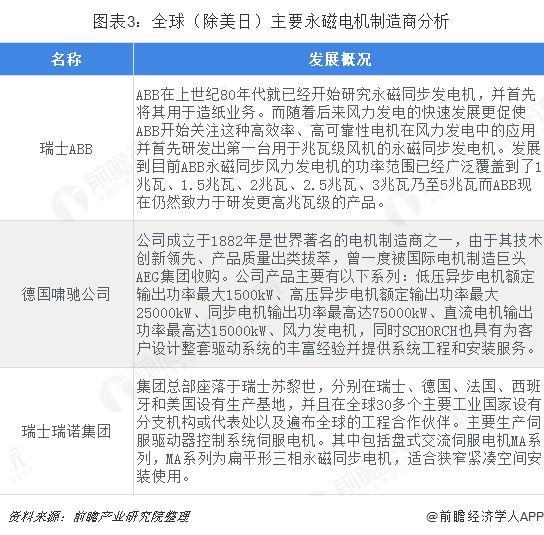

In addition to the United States and Japan, Swiss ABB, Swiss Renault Group and German Wuthering Company also have strong competitiveness and occupy a larger share of the global market.

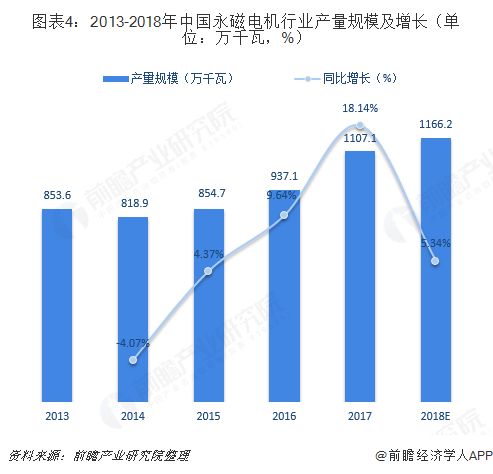

In addition, due to the gradual transfer of technology to developing countries, emerging countries represented by China also occupy an important position in the global field of permanent magnet motors. According to the statistics of the Motor Industry Association, in 2017, the output of permanent magnet motors in China exceeded 10 million kilowatts for the first time, reaching 11.07 million kilowatts, becoming the main producer of permanent magnet motors in the world.

Permanent magnetization of motor will continue

First of all, permanent magnet motor has the advantages of high efficiency, high specific power, high power factor, high reliability and easy maintenance. The variable frequency speed regulation system with vector control can make the permanent magnet motor have a wide range of speed regulation. Therefore, permanent magnetization of motor becomes one of the important development directions of motor driving technology.

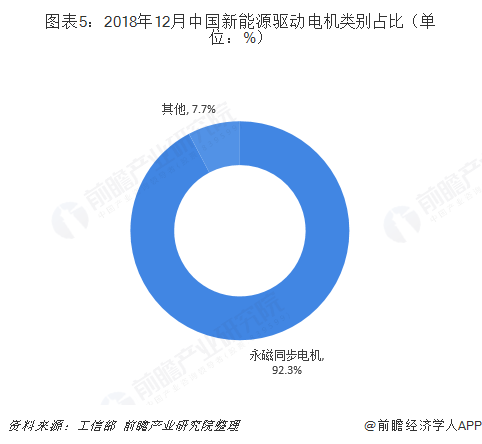

Especially in the electric vehicle motor drive technology, due to the restriction of vehicle space and use environment, the electric vehicle motor drive system is different from the ordinary electric drive system. It requires higher performance, higher volume/weight density and higher ambient temperature. The power electronics and motor technology used for ordinary motor drive can not meet its requirements. Therefore, permanent magnetization will become one of the development directions of automotive motor in the future. According to statistics from the Ministry of Industry and Information Technology, in December 2018, China's new energy passenger cars carried more than 160,000 motors, of which permanent magnet synchronous motors accounted for 92.3%.

Secondly, with the improvement of the performance of permanent magnet materials, the improvement of processing technology and the development of modern control technology, the application of permanent magnet motors in industrial and agricultural production, household appliances, medical equipment, aerospace, navigation, military and other fields will be more in-depth, and show strong vitality.

Finally, with the increasing awareness of energy saving and environmental protection, permanent magnet motors used in the field of energy saving and environmental protection will grow substantially. It can be predicted that the arrival of low-carbon economy will bring opportunities for the growth of permanent magnet motors, and super-efficient permanent magnet motors and speed-regulating high-efficiency permanent magnet motors will play an important role in energy saving and emission reduction.